In the late 1880s, Thomas Edison and George Westinghouse competed with rival electrical systems to establish which one would power the US.

George Westinghouse’s Alternating Current (AC) grid succeeded because AC power can be transmitted over long distances on thinner copper wires at high voltages. Edison’s Direct Current (DC) power is better suited to lower voltages (110V) and could only be economically transmitted a mile from the central generator on much thicker and more expensive copper wires.

For over a hundred years AC power has maintained its dominance in transmission and distribution of electrical power, and for much of that time, the vast majority of electrical equipment has been designed to run on a 60Hz (or 50Hz) Fundamental Waveform.

In the 21st century, all equipment that consumes electrical power now contains a DC circuit for microprocessor controls. This means that AC must be converted to DC, to power the electronics, and then converted back to AC to continue its path through the grid.

As AC is inverted to DC and rectified back into AC, frequencies higher than 60Hz are created. We call these harmonics.

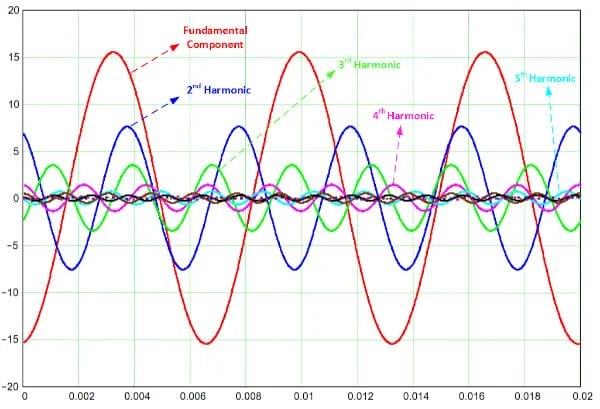

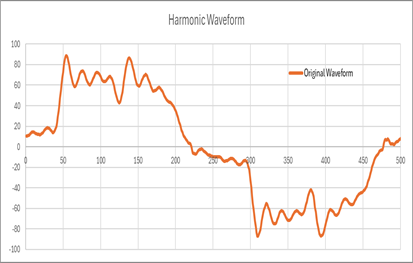

Alternating Current (AC) waveforms, operating at 60hz, should appear like a smooth sine or cosine wave. This is the most efficient waveform. Complex waveforms which are formed when additional frequencies are generated by Direct Current (DC) components in digital circuitry are the sum of those nuisance frequencies added to the fundamental frequency (60Hz).

These additional frequencies draw additional current, reducing network capacity, and cause cables and circuits to overheat and cause motors and electronic equipment to malfunction or fail. In our harmonic analysis, we generally see that odd number multiples of 60 Hz (i.e. 60 x 3 = 180, 6 x 5 = 300, etc.) have a higher impact on the waveform.

As shown in the image above, the original Fundamental waveform is distorted by the harmonic waveforms drawn by the digital elements used to control the electric motor in the equipment. 40% harmonic distortion – meaning 40% of the waveform is just nuisance noise causing additional heating and current draw.

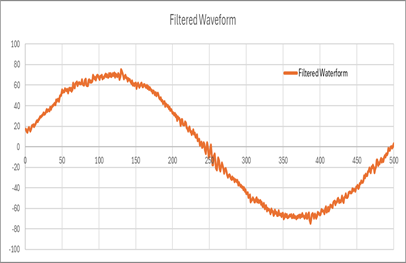

Basic Power’s custom-tuned Active Harmonic Filters (AHF) can reduce the harmonics generated by electrical equipment to <3%.

To achieve this mitigation we first conduct a power quality survey to determine the amount of voltage and current harmonics present in an electrical system and measure their frequencies, amplitudes, and phase angles. We do this with a utility-grade power quality meter that allows us to record comprehensive data.

We can then recreate the distorted waveform in our Baltimore lab and custom-tune an AHF to produce an equal and opposite waveform to cancel out any harmonics and prevent them from migrating into the electrical system where they would interfere with finely tuned medical imaging equipment and other highly specialized electronics that are susceptible to damage from the vibrations and additional heat that harmonics produce.

Most AHF on the market are pre-tuned to specific harmonic waveforms such as those created by 6 pulse drives in Variable Frequency Drives on pumps and motors. Many are built for specific drives. This means that though they can mitigate several low-order harmonics they cannot sense or mitigate higher orders. Basic Power’s custom-tuning approach is a superior method of mitigation for any harmonic-sensitive environment.